HOW MUCH HEATING OIL IS BEING WASTED?

A SEEPING EXPERIMENT IN TENAKEE SPRINGS, ALASKA.

by Kevin Allred, Toyotomi service person. 4/18/24

INTRODUCTION AND METHODS:

For years, I've noticed many of the #1 fuel oil filters and fittings associated with feeding Toyo heaters are plagued with minor seepage of oil. Typically, the oil spreads around the area of the leak causing a damp to wet surface but may not be actively dripping. The fuel is obviously evaporating faster than it can drip. These leaks cause strong odors around the leak. In worse situations, the leak forms a free drip, exceeding the evaporation rate. In my Town about 25 percent of homeowners using a Golden Rod filter experience these types of leaks, not including additional problems with seeping fittings away from the filters or associated with General Filters.

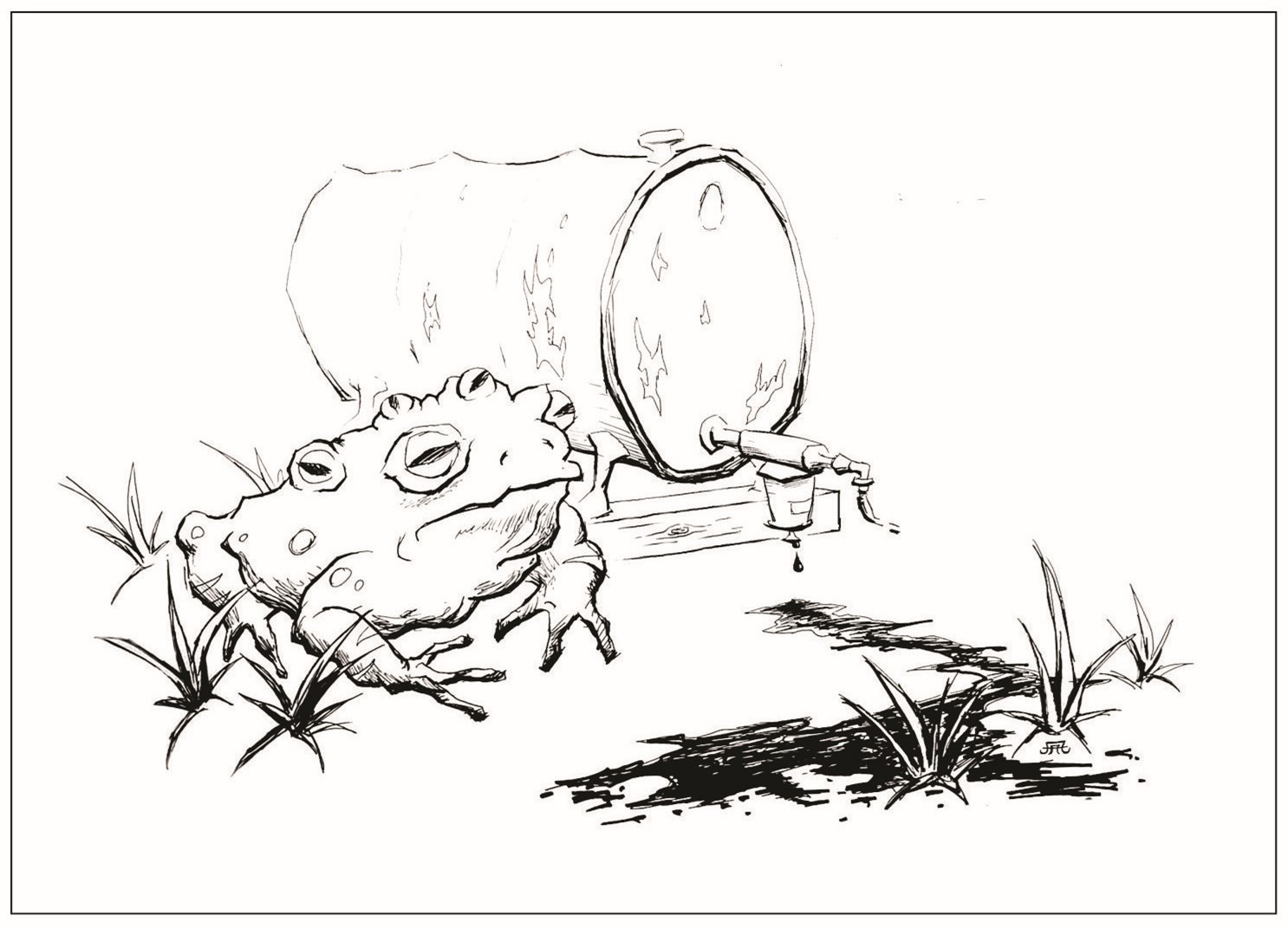

Curious about the actual rate of fuel loss, I did an experiment using a medical IV bag to time and control the rate of drip into a Golden Rod filter which was loose in its housing. A bit of sawdust on the surface of the filter bulb helped duplicate dust, dead insects, and debris often sticking to such leaks (see figure 1). This debris creates an even greater surface area for fuel oil to diffuse to and evaporate. I was unable to get the entire bulb damp, as is common in actual leaks. Thus, it is likely the actual fuel losses can be greater than my tests.

Once the drip rates were established, I went to a USGS site to determine gallons lost in time https://water.usgs.gov/edu/activity-drip.html. Since the viscosity of fuel oil is different than water, this is only an estimate. I made my measurements at approximately freezing temperatures out of the wind. I would imagine evaporation increases in breezy conditions, or when the temperatures are warmer.

RESULTS:

I found controlling the drip rate was difficult but feel confident that the produced drip rates are consistent with the minor seeps commonly observed in the field.

Below are three different drip rates with the resulting loss of gallons per day, month, and year. 1.32 minutes/drip (has a hanging drip at the bottom of the filter) leaks out .075 gallon/day, or 2.25 gallons/month, or 27 gallons/year. 2.26 minutes/drip (no hanging drip at the base of the filter) leaks out .041 gallons per day, or 1.23 gallons/month, or 14.76 gallons per year. 5 minutes/drip (no hanging drip at the base of the filter) leaks out .02 gallon/day, or .6 gallons/month, or 7.2 gallons/year.

Figure 1. In this example, fuel seepages occur all the way from the tank to beyond the filter, including the upper part of the hanging can (via the suspending wire). Note the dead insects scattered on the damp fuel surfaces. The history of this installation would indicate that over the last 16 years it has been leaking to equal at least two of the 14 gallon/year moderate seeps noted above, which equals 472 gallons total.

HOW TO STOP THESE LEAKS:

Having clean surfaces and some oil on the filter gasket helps seal the filters (using a proper filter wrench). If a sharp instrument has been used in the past to dig out the rubber gasket from the housing, there will be gouges and scratches that make a tight seal impossible. These might be carefully sanded with very fine sandpaper after removing the housing for easier access. But it might be better to just buy new filter housing. If the water drain at the bottom of Golden Rod filters has been tightened with pliers or wrench, the bulb threads may crack open later, causing a major fuel leak. General Filters may have issues with scratches, casting porosity, or rust on their sealing surfaces.

It is common for homeowner flare fittings to leak, and these should be re-flared properly to stop seepages there. I like to use the heavier "refrigeration" flare nuts, which are less likely to go egg-shaped like the cheesy 3/4" flare nuts do. Teflon tends to cause leaks when used on fittings, and my recommendation is to clean the threads well of any paint, debris, old sealant, and Teflon, then use "Leak Lock" thread sealant for all connections except the flare itself. No Teflon should be used for the flare surfaces. A water drain system below the small bung at the tank bottom is recommended with a separate valve and safety plug below the valve. I use Teflon on the threads of the safety plug, which is removed each time water is regularly drained from the tank. At the top of the tank, use Leak Lock on all the fittings except the fill cap. This will help keep water out of the tank, filters and fuel lines, where water and expanding ice will play havoc with things, possibly causing major fuel leaks. Finally, tanks themselves do not last forever, and will eventually begin leaking where moist wood touches them, or at their bases where they rust through (Figure 2).

Figure 2. This old cylindrical tank (up ended) had three different places dampness indicates seeps. Upon probing the center one, a 1/8" hole appeared in an old dent, which had been temporarily partially plugged with inner sludge, keeping the leaking minimal, but constant. These old tanks should be pumped out and replaced; especially the 55-gallon drums, which don't last long at all.

CONCLUSIONS:

As observed, the minor seepages from fuel oil leaks seem insignificant, but over time they can be wasteful and costly, causing a fuel smell in the area. It is a good idea to do what we can to encourage homeowners to fix these and make Toyo installations as safe and clean as possible.